AUTO SHANGHAI 2025 is in full swing, while recent legal disputes and public controversy surrounding several accidents involving driver assistance systems continue to reverberate throughout the industry.

A week prior to AUTO SHANGHAI 2025, the Ministry of Industry and Information Technology (MIIT) issued an announcement titled "First Department of Equipment Industry Holds Work Promotion Meeting on Product Market Access and Software Upgrade Management for Intelligent Connected Vehicles" (hereinafter referred to as the "Announcement").

The Announcement emphasized the need to fully conduct testing and validation of combined driving assistance (CDA) systems, clearly define system functional boundaries and safety response measures, refrain from exaggerated and false advertising, strictly fulfill information disclosure obligations, earnestly assume responsibility for production consistency and product quality safety, and effectively enhance the safety level of intelligent connected vehicle (ICV) products. This move authoritatively pressed the "standardization button" for the industry.

Prioritizing Quality, Safeguarding the Automotive Safety ‘Nerve Endings’

As the ‘nerve endings’ of intelligent driving, sensor reliability is paramount to system safety. Audiowell consistently upholds its core philosophy of ‘being good people and making good products to create a better life together,’ ensuring meticulous care in every delivery. Taking the VU0004 ultrasonic sensor as an example: every unit must undergo 38 testing procedures before shipment—fully demonstrating the production philosophy of prioritizing quality above all else.

Extreme Environment Validation

Underwent 100 cycles of alternating high/low temperature testing to ensure measurement stability in extreme cold and high-heat scenarios

Multi-physical Field Interference Testing

Underwent comprehensive validation including:

Radiated Immunity Testing (per ISO 11452-2);RF Conducted Immunity Testing (per ISO 11452-4);Electrical Transient Conduction Testing (per ISO 7637-3);Transient Conducted Immunity Testing (per ISO 7637-2)to ensure product compliance with EMC requirements.

Short-Circuit Protection Test

During operation, each pin was individually short-circuited to power and ground. Test results confirmed the product's ranging capability remained compliant with specifications.

Compliance with ISO 26262:2018 ASIL-B Functional Safety

Audiowell strictly adheres to the ISO 26262 functional safety development process for product design, achieving ASIL-B requirements per the globally recognized automotive functional safety standard. This provides safety protection solutions for Combined Driving Assistance (CDA) applications, meeting functional safety development requirements of world-class OEMs and Tier-1 suppliers.

Behind such rigorous metrics lies a "zero-failure" design principle. When sensors detect obstacles, they must complete the signal acquisition-processing-transmission chain within an extremely short timeframe, securing critical braking windows for decision-making systems.

While spotlight-stealing innovations dazzle at Auto SHANGHAI, true auto engineers remain focused on the embedded safety DNA within.

As Audiowell adheres to its "38-step process with zero-defect tolerance" principle in sensor validation, every product evolution remains grounded in systematic safety design.

As early as February 2023, Audiowell obtained ISO 26262:2018 ASIL D Development Process Compliance Certification from TÜV Rheinland. This milestone confirms the company has established a product development process system compliant with the highest functional safety level (ASIL D) per ISO 26262:2018 requirements, achieving globally advanced standards.

We recognize this fundamental truth: Only by establishing a full lifecycle safety ecosystem spanning R&D, manufacturing, and maintenance can we truly achieve "Embracing Innovation, Sharing a Future."

The future has arrived, but no shortcuts exist in safety.

Comprehensive Product Solutions Safeguarding Mobility Safety

Automotive Wading Detection Solution

This solution utilizes ultrasonic sensing technology to determine vehicle wading status by analyzing echo signal variations across different media. It accurately measures water depth, integrates with vehicle safety systems, and provides multi-level alerts (safe wading level / cabin intrusion level / engine flooding risk) to ensure driving safety in wading scenarios.

- Precise Water Depth Monitoring: Effective for urban flooding and shallow fords

- Functional Synergy with AK2 Ultrasonic Radars: Enables hardware reuse

- Accurate Wading Depth Detection: Enhances driving adaptability in challenging road conditions

Ultrasonic Lens Cleaning Solution

Audiowell's ultrasonic lens cleaning solution employs proprietary materials and algorithms to enable camera systems to rapidly detect and remove contaminants (water, ice, etc.) affecting image clarity through high-frequency oscillation. Compared to traditional cleaning methods, this solution delivers superior cleaning quality, faster operation, minimal component wear, and fully autonomous operation.

- Cleaning Quality Assurance: Minimal residual contamination

- AI-Driven Debris Identification: Enables intelligent system control

- Rapid Cleaning Cycles: Enhanced operational efficiency

- Oscillation-Based Contaminant Removal: Minimal wear on lens components

AK2 Ultrasonic Radar

A next-generation intelligent automotive sensor based on ultrasonic ranging principles, outperforming market alternatives with extended detection range and minimized blind zones. Designed for Parking & Driving Integration (PDI) systems, it utilizes industry-leading DSI3 communication protocol for high-speed synchronized data processing while meeting ASIL B functional safety requirements – making it an essential perception hardware for future intelligent driving platforms.

- APA & UPA Fusion: Integrated long/short-range detection capabilities

- Coded Modulation: Advanced interference mitigation technology

- DSI3 Interface: High-speed signal transmission architecture

- ASIL B Functional Safety: Automotive Safety Integrity Level B compliance

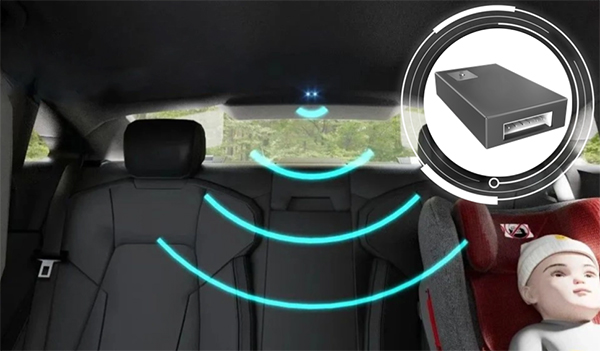

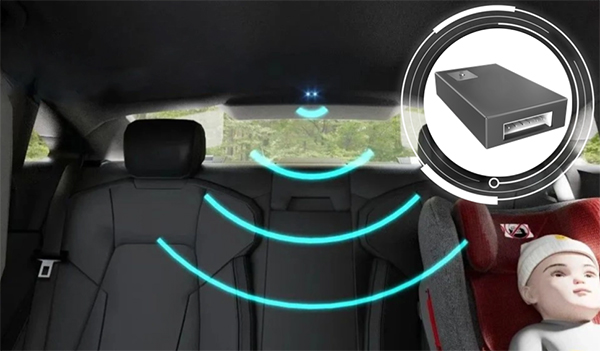

Child Presence Detection (CPD) Solution

This system employs Audiowell's self-developed ASIC and MEMS ultrasonic transceiver sensors with integrated microcontrollers for signal processing and communication. By emitting periodic and aperiodic ultrasonic waves into cabin spaces and analyzing reflected echoes, it identifies spatial disturbances through signal feature extraction to detect living occupants' micromovements.

- Ultra-Compact Design: 2.2mm mounting aperture

- Stealth Installation Capability: Seamless vehicle integration

- Wide Detection Coverage: 120° field of perception

Focus on us

Focus on us