In June, AUDIOWELL ROBOTICS will be at the Shenzhen International Exhibition, showcasing its full range of precision dispensing products covering ‘components-parts-workstations.’ Exhibits will include piezoelectric stacks, piezoelectric jet valves, piezoelectric controllers, and six-axis multi-head precision dispensing robots, fully meeting the needs of the precision manufacturing industry.

One-stop service for multiple adhesives and multiple bonding processes

Six-axis precision dispensing robot

The six-axis multi-head precision dispensing robot is a highly automated and intelligent industrial robot device suitable for precise dispensing operations in various complex production processes. The robot has six degrees of freedom in its turning axes, providing flexible and precise dispensing paths. The product can be equipped with multiple dispensing heads to simultaneously perform various precise and difficult dispensing tasks.

- High efficiency: supports synchronous or asynchronous multi-valve operation

- High flexibility: compatible with different valve bodies, various adhesives, and functional modules

- High applicability: adapts to different surfaces and processes

- High precision: repeat positioning accuracy of ±0.02 mm

Piezoelectric injection valve

The piezoelectric jet valve employs AUDIOWELL's proprietary piezoelectric stack drive technology, ensuring product stability, consistency, and an exceptionally long service life. It features a quick-release function for the feed component and a rapid adjustment function for the needle position, significantly reducing maintenance time and enhancing production efficiency. It is widely applicable for non-contact jet dispensing of various fluids, such as conductive silver paste, IC encapsulation adhesive, red adhesive, UV adhesive, silver adhesive, underfill adhesive, and other types of fluids.

- Maximum operating frequency of 1500 Hz.

- Minimum dispensing volume of 1 nL, capable of achieving a line width of 0.15 mm with 99% accuracy.

- Compatible with any dispensing platform on the market.

Piezoelectric Controller

The piezoelectric controller uses a high-precision control circuit to accurately control the piezoelectric spray valve for precision dispensing, achieving a fast dispensing rhythm while meeting high-precision and stable dispensing requirements. The multi-channel switching function enables a simple parameter configuration mode. By switching dispensing modes, you can easily switch between dot and line modes, making it suitable for a wide range of dispensing applications.

- Simple interface and easy operation

- Smooth filtering of drive signals for more stable dispensing

- Power-off parameter retention, no need for repeated debugging

- Precise adjustment of various parameters to meet different dispensing needs

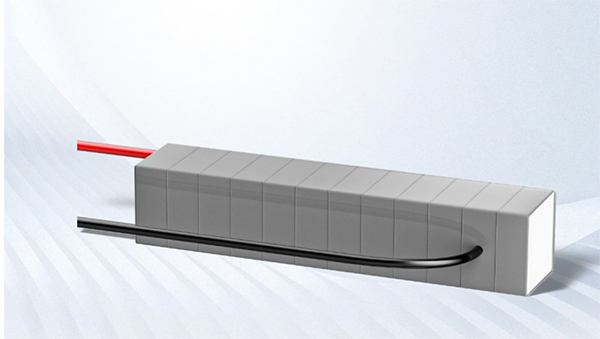

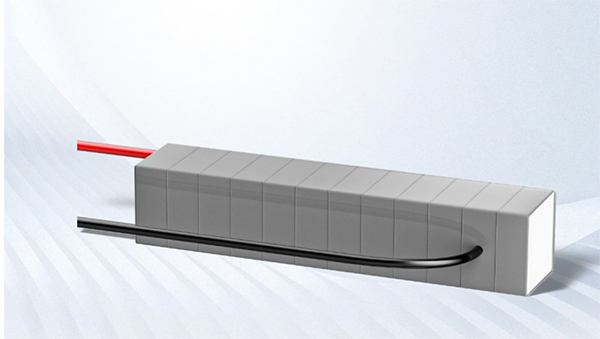

Piezoelectric Stacked Layers

Piezoelectric stacked layers are multi-layer piezoelectric ceramics formed by bonding multiple piezoelectric ceramic films through a hot-press bonding and co-firing process. They utilize the inverse piezoelectric effect to convert electrical energy into mechanical energy. These products offer advantages such as high resolution, high-precision displacement, fast response speed, compact size, and high output force. They are widely applied in fields such as high-precision valve control and micro-displacement control platforms.

- Micron-level high-precision displacement

- Millisecond response speed

- Small size, high output

- Wide operating temperature range, suitable for multiple scenarios

There are even more high-end smart manufacturing application products awaiting your arrival!

About AUDIOWELL ROBOTICS

AUDIOWELL ROBOTICS was established in 2016 and is a high-tech enterprise specialising in the research, development, design, manufacturing, and sales of intelligent robots, smart manufacturing equipment, and key core components.

As a wholly-owned subsidiary of AUDIOWELL, AUDIOWELL ROBOTICS has assembled a professional team with extensive experience in R&D, design, and manufacturing by integrating superior resources. The company is committed to providing high-tech, precision, and cutting-edge intelligent robots and intelligent manufacturing equipment to support production line upgrades for intelligent manufacturing enterprises.

The company's main products include: six-axis multi-head precision dispensing robots, precision force-controlled robotic arms, flexible manufacturing automation systems, piezoelectric spray valves, precision force-controlled grippers, and other products and solutions, which are widely applied across industries such as electronics, communications, automotive, and semiconductors.

Focus on us

Focus on us