In recent years, the concept of unmanned has been gradually applied to various industries in society, such as unmanned retail, unmanned drive, and unmanned factory; Related to logistics are unmanned sorting robots, driverless trucks and forklifts. More and more new equipment has also been put into practical use.

Warehouse management plays a central role in logistics management. There are many disadvantages in traditional warehousing management. Through intelligent logistics, upgrading equipment technology, improving automation level, and realizing the strategy of replacing human beings with machines, the existing pain points of warehousing logistics management can be effectively solved. Among them, automated guided vehicle (AGV) is an essential tool in intelligent logistics warehouse.

AGV mainly realizes the function of positioning goods, picking goods with the optimal path, and then automatically sending goods to the destination. Whether it is navigation planning or obstacle avoidance, sensing the surrounding environment information is the first step. For obstacle avoidance, mobile robots need to obtain the information of obstacles around them in real time through sensors, including size, shape, position and other information. There are many kinds of sensors used in obstacle avoidance, each with different principles and characteristics. At present, the common ones are ultrasonic sensors, visual sensors, laser sensors, infrared sensors, etc.

Among them, ultrasonic sensor is a scheme with low cost, simple implementation method and mature technology. It uses ultrasonic sensor to avoid obstacles, that is, the piezoelectric or electrostatic transmitter generates an ultrasonic pulse with a frequency of dozens of kHz to form a wave packet. The system detects the reverse sound wave higher than a certain threshold, and then uses the measured flight time to calculate the distance, so as to obtain the information of obstacles around itself in real time, Including the size, shape and position of obstacles.

As the eye of robot and the obstacle avoidance problem in the field of AGV, audiowell has launched a vehicle specification level ultrasonic sensor to replace the traditional infrared and laser sensors, which can help the storage AGV realize autonomous obstacle avoidance in the warehouse. When multiple cars cross drive, they can stop in time and accurately to avoid collision. The ultrasonic sensor can detect the range of 90 ° horizontal viewing angle and 45 ° vertical viewing angle, and the effective detection distance is 5m, so as to ensure higher reliability and stability. Compared with the single level detection of 2D scanning radar, the sensor can better avoid low obstacles on the ground.

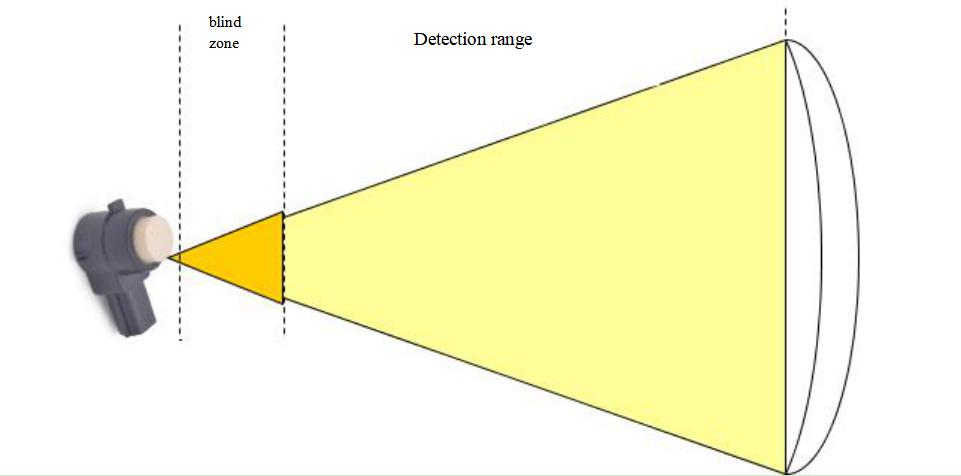

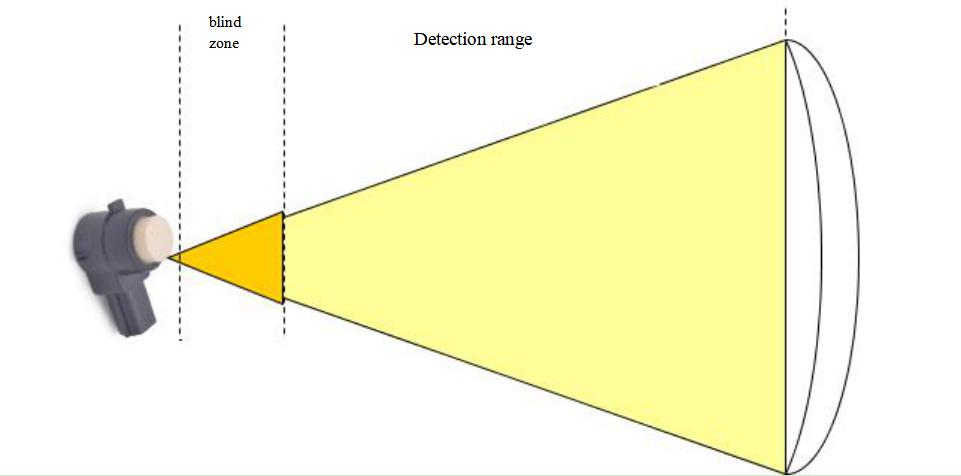

The sensor emits ultrasonic waves, and the sound travels in a cone , so the actual measured distance is not a point, but the distance of the nearest object within a conical angle range. The built-in obstacle avoidance algorithm of the ultrasonic sensor deeply integrates and processes all obstacle information within the field of view, and finally outputs only the azimuth information of the obstacle closest to the robot.

When the sensor detects an obstacle and enters the warning area, the sensor will feed back the azimuth information of the obstacle nearest to the robot to the AGV control system in time, and the control system will control the robot to slow down and brake. For those obstacles that are not in the forward area of the robot, even if they are close, the radar will not give warning, so as to ensure the efficiency of robot operation. The robot can continue to work only after the obstacle leaves or is designed to bypass the obstacle. In practical application, it is only necessary to set AGV width and obstacle avoidance range, without secondary data development.

The vehicle carries out local path planning through laser point cloud and high-precision map, and obtains several tracks to be selected. Then, the obstacle information obtained by ultrasound is projected and calculated back to the vehicle coordinate system. The obtained trajectory to be selected is further screened and modified, and finally the optimal trajectory is obtained, and the vehicle motion is controlled according to the optimal trajectory. When the vehicle is in the forward state and the obstacle distance obtained by the ultrasonic wave in front is less than the safe distance of the vehicle, the vehicle will make an emergency stop. The same is true when the vehicle is in the reverse state.

Audiowell ultrasonic sensor

- Direct output digital signal

- Equipped with matching circuit to optimize the performance of the sensor

- High measurement accuracy

- Ip69 protection grade

At present, the ultrasonic sensor researched by Audiowell has been applied to AGV , intelligent robots and other products. In the future, Audiowell will strive to become a major global supplier of sensors (position, distance, speed) and their application solutions, invest more focused and professional research in sensor "sensing and obstacle avoidance" ranging, and create a smart life with sensor technology.

Focus on us

Focus on us