On July 30th, Audiowell will showcase its industrial intelligent robot product solutions at the 2025 (6th) World AI Expo & Smart Industry Exhibition (WAIE). These solutions will empower precision manufacturing equipment, laser production equipment, and intelligent sorting systems to achieve more refined, accurate, and intelligent production upgrades.

Intelligent Manufacturing, Empowering Industrial Upgrades

WAIE Smart Industry Expo

Date: July 30 - August 1, 2025

Venue: Shenzhen Convention & Exhibition Center (Futian)

Audiowell Booth: Hall 1, D221

Precision Manufacturing Equipment Application Solutions

6-Axis Multi-Head Precision Dispensing Robot

The 6-Axis Multi-Head Precision Dispensing Robot is a highly automated and intelligent industrial robotic system designed for precise dispensing operations in complex production processes. Featuring six degrees of freedom, it delivers flexible and accurate dispensing paths. The system supports multiple dispensing heads, enabling simultaneous execution of various precision, high-difficulty dispensing tasks.

- High Efficiency: Supports synchronous or asynchronous multi-valve operation

- High Flexibility: Compatible with different valve bodies, various adhesives, and functional modules

- High Adaptability: Suitable for different surfaces and processes

- High Precision: Repeat positioning accuracy ±0.02mm

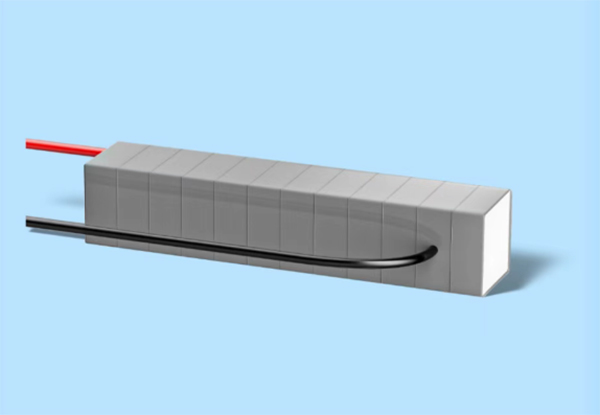

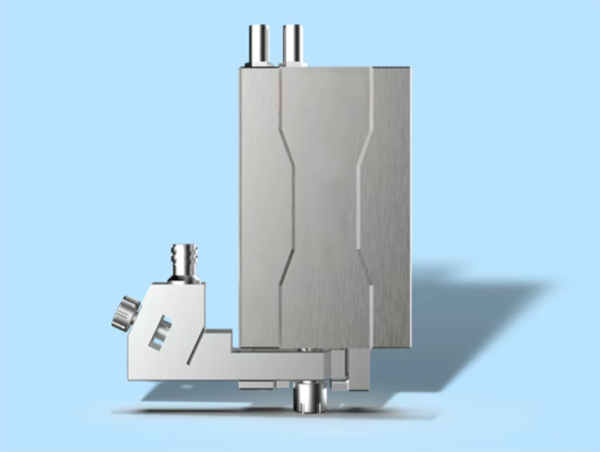

Piezoelectric Jet Valve

Utilizing Audiowell's self-developed piezoelectric stack drive, the Piezoelectric Jet Valve ensures product stability, consistency, and extended lifespan. Features like quick-disassembly for the glue inlet assembly and rapid needle position adjustment significantly reduce maintenance time and boost production efficiency. Widely applicable for non-contact jetting of various fluids such as conductive silver paste, IC underfill, red glue, UV adhesive, silver glue, etc.

- Minimum Jetting Volume: 1nL, achieving 0.15mm line width

- Precision: Up to 99%

- Compatibility: Integrates with any dispensing platform in the market

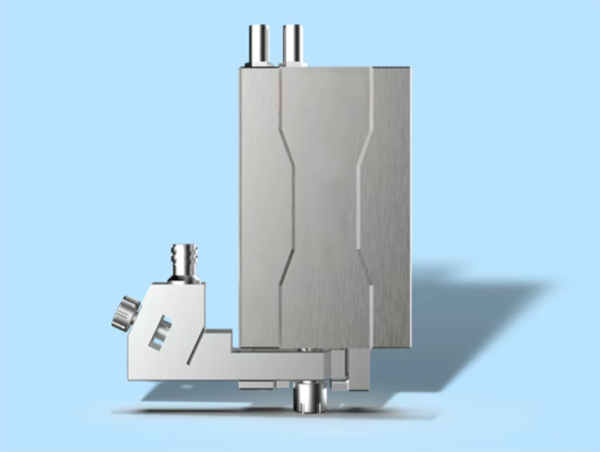

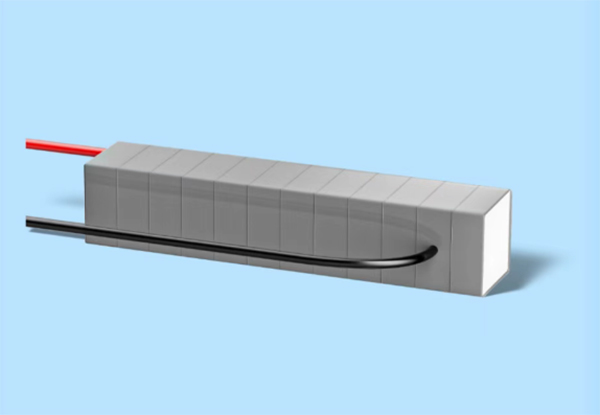

Piezoelectric Stack

A piezoelectric stack is a multilayer piezoelectric ceramic formed by bonding multiple piezoelectric ceramic films through a hot-pressing co-firing process. Leveraging the inverse piezoelectric effect, it converts electrical energy into mechanical energy. The product offers advantages like high resolution, high-precision displacement, fast response, compact size, and high force output. It is widely used in high-precision valve control, micro-displacement stages, and other fields.

- Micron-level high-precision displacement

- Millisecond response speed

- Compact size, high force output

- Wide operating temperature range, suitable for multiple scenarios

Laser Production Equipment Application Solutions

Vortex Flow Sensor

The Vortex Flow Sensor for laser production equipment features fast response and dual-parameter detection (flow and temperature). It quickly detects coolant flow anomalies (e.g., sudden drops due to pump failure or pipe blockage) and triggers protective mechanisms (e.g., reducing laser power or shutdown), effectively preventing equipment damage from overheating. This solution upgrades flow monitoring from "pressure-dependent" to "dynamic prevention," making it an optimal choice for safeguarding high-value laser production equipment. The sensor is unaffected by bubbles or impurities, ensuring stable and reliable performance. Its wide turndown ratio accommodates flow variations under different power outputs (corresponding to varying cooling demands), eliminating the need for frequent sensor replacement.

- Utilizes self-developed core components with strong resistance to bubble and impurity interference

- Modular structure, low pressure loss, low energy consumption

- Instantaneous flow accuracy: ±3% F.S.

- Available in multiple nominal diameters: DN10, DN15, DN20, DN40

Ultrasonic Flow Sensor

The Ultrasonic Flow Meter employs the bidirectional time difference method (measuring the ultrasonic propagation time difference between upstream and downstream flows) to accurately detect minute flow changes. It features micro-flow leak detection capability, enabling rapid capture of abnormal flow fluctuations. This triggers protective mechanisms (e.g., shutdown or pump speed adjustment) promptly to prevent equipment damage caused by cooling failure, meeting the stringent thermal management requirements of laser production equipment.

- Optional multi-parameter detection modules (e.g., pH, conductivity) for versatile use

- No moving parts internally, ensuring high measurement accuracy

- Micro-flow leak detection, extended product lifespan

- Available in multiple nominal diameters: DN15, DN20, DN25

Intelligent Sorting Equipment Application Solutions

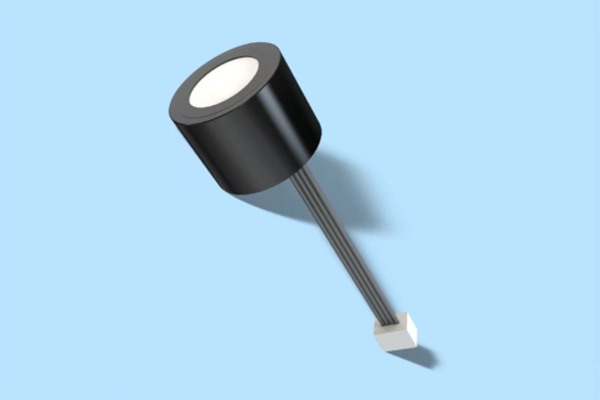

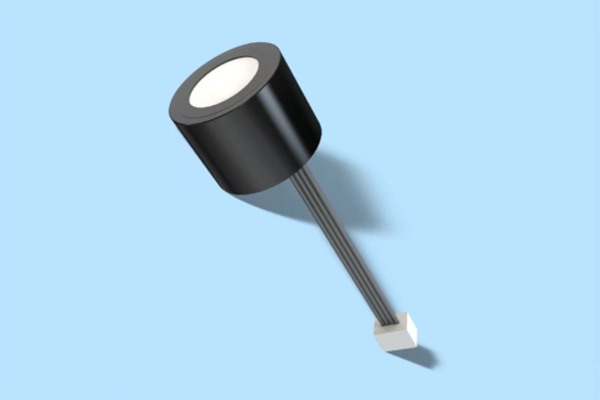

Material Identification Sensor

The Ultrasonic Material Identification Sensor emits ultrasonic waves and receives reflected or transmitted echo signals from objects. By analyzing signal characteristics, it identifies material types. Unaffected by object color, surface pattern, or ambient lighting conditions, it effectively compensates for the limitations of visual recognition in material differentiation. Particularly useful for distinguishing objects with highly similar visual appearance (e.g., color, texture) but different materials (e.g., verifying correct assembly of small bottle cap sleeves), the ultrasonic sensor provides rapid, precise identification at the millimeter scale, significantly enhancing the reliability and application scope of intelligent sorting equipment.

- Unaffected by object color, surface pattern, or ambient lighting conditions

- Enables precise material identification within millimeter ranges

Precision Force-Controlled Gripper

The Precision Force-Controlled Gripper integrates high-sensitivity force sensors and a real-time closed-loop feedback control system to dynamically sense contact forces during gripping. It actively adjusts the output gripping force based on the material properties of different objects (e.g., rigidity, elastic modulus, fragility). This ensures secure handling while keeping contact stress within the material's safe threshold when grasping deformable items (e.g., food), scratch-prone items (e.g., 3C product housings), or highly fragile items (e.g., chips, glass components), maintaining object integrity. It enhances the reliability and applicability of intelligent sorting equipment in food engineering, 3C accessory assembly, chip packaging, and other precision manufacturing processes.

- Capably handles fragile and brittle workpieces

- Highest precision up to 0.01N

- Supports multiple motion control methods

Focus on us

Focus on us