From August 13th to 15th, 2025, the highly anticipated 33rd China International Measurement Control and Instrumentation Exhibition (MICONEX) will be grandly held at the Hunan International Convention and Exhibition Center in Changsha. Audiowell (Booth: A1033, Hall E1), as one of the exhibitors, will showcase its leading ultrasonic smart flow measurement product series and solutions.

Exhibition Name: The 33rd China International Measurement Control and Instrumentation Exhibition (MICONEX)

Dates: August 13-15, 2025

Venue: Hunan International Convention and Exhibition Center, Changsha

Audiowell Booth: A1033 (Hall E1)

Smart Water Meter Application Series

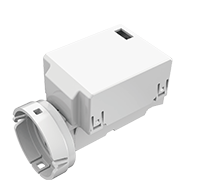

Lead-free Flow Transduser

The Lead-free Flow Transduser is an environmentally friendly flow transducer based on new material technology, containing no lead elements and complying with advanced international environmental standards. It calculates liquid flow rate by measuring changes in ultrasonic speed within the pipe, thereby determining the liquid flow volume over a specific period. It is suitable for smart water meters, smart irrigation systems, building water management systems, and whole-house water purification systems.

- Eco-friendly lead-free piezoelectric material, compliant with multiple international drinking water standards.

- Resistant to high/low temperatures and high pressure.

- High stability and reliability.

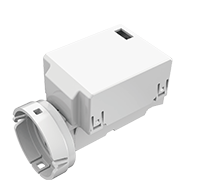

High-Temperature Flow Transducer

Audiowell's High-Temperature Flow Transducer is an ultrasonic sensor for liquid media. Constructed with highly pressure-resistant materials like stainless steel and ceramics, and featuring a highly sealed design, it can directly contact liquids. It avoids issues related to unstable pressure and heat resistance, ensuring more stable performance, reducing environmental interference with signal transmission/reception, and effectively enhancing response sensitivity.

- Withstands temperatures up to 240 °C.

- Long-term pressure tolerance up to 2.5MPa.

- Low driving voltage (5Vp-p), compliant with EU/US detection requirements, excellent consistency.

- Probe diameter of 16.8mm for wide applicability.

Ultrasonic Flow Sensor

Audiowell's self-developed Ultrasonic Flow Sensor is a plastic pipe section specifically designed for ultrasonic water meters. Equipped with built-in ultrasonic transducers, it measures forward/reverse flow velocity to determine flow rate, serving as the data foundation for ultrasonic water meter metering. With no internal moving parts to cause turbulence, it offers high measurement accuracy. The internal sensors comply with multiple countries' drinking water standards.

- High detection precision via ultrasonic measurement.

- No internal moving parts, eliminating turbulence.

- Housing made from new eco-friendly materials.

- Internal transducers comply with multiple countries' drinking water standards.

Smart Gas Meter Application Series

Gas Flow Transducer

The Gas Flow Transducer is the core component of ultrasonic gas meters. This ultrasonic sensor for gas media utilizes new acoustic matching materials to enhance ultrasonic signal transmission capability in gas. Primarily used for natural gas and coal gas metering.

- High sensitivity.

- Excellent directivity.

- Corrosion-resistant materials suitable for various gases.

Gas Flow Sensor

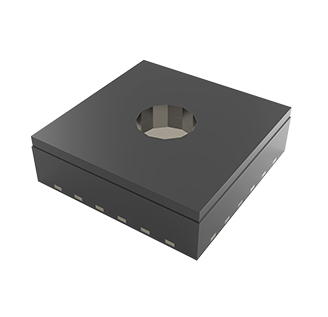

The Gas Flow Sensor consists of the Gas Flow Transducer and housing. Its conveniently installable housing, formed by upper and lower covers, incorporates ultrasonic sensors using new acoustic matching materials to improve signal transmission in gas. Primarily used for natural gas and coal gas metering.

- Combined structure for easy installation.

- Stable and reliable quality.

- Excellent consistency.

Intelligent General-purpose Liquid Flow Measurement Series

Ultrasonic Flow Sensor Model

This pipe-section ultrasonic flow sensor Model outputs direct digital flow signals. It integrates a pair of master-slave connected ultrasonic flow sensors and a measuring pipe section, along with circuitry for processing time-difference signals of ultrasonic propagation. It outputs digital information such as instantaneous flow, total flow, and water flow status via serial interface.

- High measurement accuracy with no moving parts.

- Micro-leak detection for intelligent alerts.

- Flexible expansion, multiple applications.

- Supports liquid and semi-fluid flow measurement.

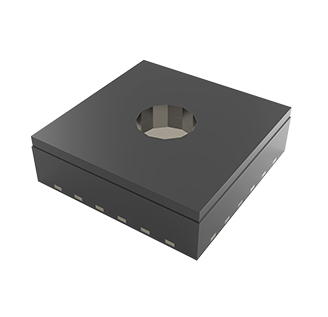

Vortex Flow Sensor

The Vortex Flow Sensor measures liquid or gas flow, especially suited for large flow, high velocity, and high-viscosity coolant scenarios. Based on the Kármán vortex street principle, it accurately detects vortex frequency generated as fluid passes a bluff body. Combined with fluid dynamics models and signal processing, it enables stable, real-time flow measurement.

- Excellent resistance to bubble and impurity interference.

- Modular structure with low pressure loss.

- Instantaneous flow accuracy ±3% F.S.

- Optional temperature sensor for simultaneous flow/temperature detection.

Clamp-on Flow Sensor

This clamp-on, non-contact flow measurement device features two ultrasonic sensors continuously transmitting ultrasound towards the pipe center and receiving echoes. By measuring ultrasonic propagation time within the pipe section, it calculates the velocity and flow rate of the liquid inside.

- Non-contact high-precision measurement via external clamping.

- Compatible with rigid metal pipes and flexible plastic pipes.

- Suitable for various fluids like water, ethanol, and chemical solutions.

Intelligent Gas Flow Measurement Series

MEMS Ultrasonic Gas Flow Measurement integrates the physical principle of sound velocity difference with Micro-Electro-Mechanical Systems (MEMS) technology. It achieves reliable metering through high-precision Time-of-Flight (TOF) algorithms and dynamic composition compensation. Its core advantages are low power consumption, long lifespan, and anti-aging, making it ideal for smart metering and Industrial IoT, ushering gas flow measurement into the digital era.

- Enables high-precision detection of small flows.

- High integration, compact size, meeting meter miniaturization trends.

- Mature process, excellent consistency in mass production.

Focus on us

Focus on us