From November 18 to 20, 2025, Audiowell will showcase innovative energy metering products, including the Energy Meter - MEMS Solution, at the Enlit Europe exhibition in Bilbao, Spain.

With the accelerated integration of renewable gases like biomethane and hydrogen into energy grids, significant variations in gas calorific values have rendered traditional volumetric metering inadequate for equitable billing. The Energy Meter - MEMS Solution utilizes a MEMS ultrasonic sensor array. By analyzing the impact of different gas components on ultrasonic absorption and propagation velocity, it enables multi-gas component identification and precise energy consumption calculation, providing reliable technological support for advancing intelligent and efficient energy metering.

Energy Meter - MEMS Solution Debut at Enlit Europe

Multi-Component Gas Identification

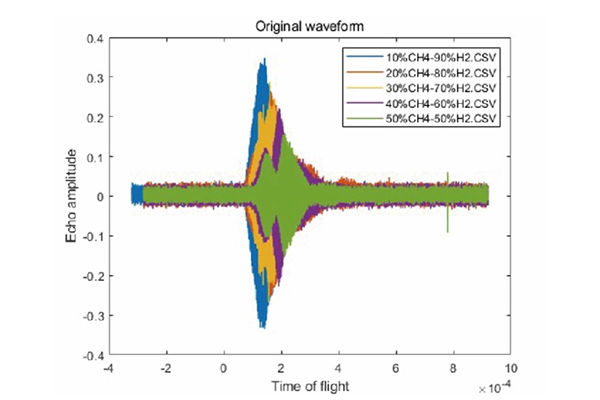

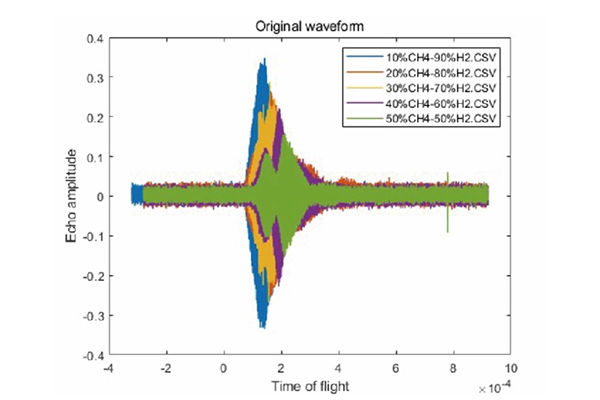

By employing an array of MEMS ultrasonic transducers operating at different frequencies, the system captures multi-dimensional acoustic characteristics of gas samples. Each gas component possesses unique acoustic absorption spectra and sound velocity features at specific frequencies, forming a "fingerprint" database for gas identification.

As illustrated in the figure above, when ultrasonic waves pass through a gas mixture, waves of different frequencies undergo varying degrees of attenuation and velocity changes. Analyzing these variations allows for the determination of the proportional composition of the gas mixture.

This solution can identify various gas mixtures, including natural gas, liquefied natural gas (LNG), biomethane, hydrogen-blended gas, and pure hydrogen.

Self-Calibration Mechanism

The sensor array integrates advanced MEMS technology and SMT (Surface Mount Technology) processes, combining ultrasonic transmission and reception functions. The solution incorporates multiple self-calibration techniques, enabling real-time self-calibration through the array of MEMS ultrasonic transducers operating at different frequencies.

Energy Consumption Value Output

The sensor array covers a broad frequency range to acquire sufficient gas acoustic characteristic information. The fully automated sampling process converts gas composition and flow data into energy consumption values.

This solution is suitable for various application scenarios, including urban gas metering, biomethane monitoring, hydrogen blending systems, and industrial process gas analysis. As countries successively announce hydrogen energy strategies—for example, the UK and the Netherlands mandating that all boilers sold from 2025 must be hydrogen-ready—market demand for multi-gas energy measurement systems is expected to grow significantly.

More Energy Metering Application Products

Gas Energy Metering Application Series

MEMS Gas Flow Sensor

The MEMS gas flow sensor measures approximately 2.8×2.8×1 mm, contains no moving parts internally ensuring an unobstructed flow path, and utilizes the ultrasonic direct Time-of-Flight (dToF) principle for precise measurement. With a 450kHz resonant frequency paired with a dedicated horn to enhance signal strength, it effectively overcomes the signal attenuation issues of traditional sensors at low flow rates. It is suitable for small pipe diameter, low flow rate applications, and its measurement results are unaffected by factors such as gas composition or concentration.

- Over 190 times smaller than conventional ultrasonic sensors, achieving a high degree of miniaturization.

- No moving parts inside the sensor, ensuring accurate measurement.

- Requires only 30dB gain for full-scale output, significantly improving the signal-to-noise ratio.

- Low startup flow rate, supports leak diagnosis.

Gas Flow Transducer

The gas flow transducer is a core component of ultrasonic gas meters, functioning as an ultrasonic transducer for gas media. Audiowell utilizes composite materials to create high-performance matching layers, enhancing the transducer's ability to transmit ultrasonic signals in gas media. It has developed high-frequency, high-sensitivity, high-precision sensors with various transmission frequencies such as 200 kHz and 500 kHz, providing accurate sensing data for the iterative upgrade of ultrasonic meters for natural gas, coal gas, etc.

- Manufactured with composite materials to create high-performance matching layers.

- High frequency, high sensitivity, and high precision.

- Different transmission frequencies available for selection, such as 200 kHz and 500 kHz.

Liquid Energy Metering Application Series

Lead-Free Flow Transducer

The lead-free flow transducer is an environmentally friendly ultrasonic transducer for liquid media based on new material technology. Its built-in piezoelectric ceramic uses self-developed materials (containing no lead elements), complying with current international advanced environmental standards, ensuring a more eco-friendly and precise sensing device for liquid measurement.

- Self-developed new material technology: lead-free and environmentally friendly.

- High quality, compliant with international environmental regulations such as REACH, RoHS, and WRAS.

- Resistant to high and low temperatures, meeting stability test requirements in high-pressure environments up to 4.8 MPa.

High-Temperature Flow Transducer

The Audiowell High-Temperature Flow Transducer is an ultrasonic sensor for liquid media. Constructed from high-pressure-resistant metals and other special materials, it features a highly sealed design allowing direct contact with liquids. This design avoids issues of unstable pressure and heat resistance, resulting in more stable product performance, reduced interference from environmental factors on signal transmission and reception, and effectively improved response sensitivity.

- Withstands high temperatures up to 240°C.

- Can endure long-term pressure of 2.5 MPa.

- Low drive voltage down to 5 Vp-p, with good consistency.

- Probe diameter of 16.8 mm, offering wide applicability.

Flow Transducer with Pipe

This product employs ultrasonic sensing technology, integrating a pair of sensors into the meter body pipe section. It accurately calculates flow velocity and cumulative flow by detecting the time difference of ultrasonic wave propagation in downstream and upstream directions. It offers pipe section materials in copper and plastic, supports various nominal diameters (DN) such as DN15, DN20, and DN25, adapts to different installation environments, and combines measurement accuracy with structural reliability.

- Long-term pressure resistance up to 2.5 MPa.

- Supports various nominal diameters such as DN15, DN20, and DN25.

- Provides different pipe section materials like copper and plastic.

Focus on us

Focus on us