In strict alignment with the policy directives of the National Work Plan for Special Action on Urban Gas Safety, the industry's technological focus is shifting towards "preventive measures and process monitoring." Ultrasonic measurement technology, known for its precision and reliability, has become a key enabler. This month, at the 27th China International Gas & Heating Technology and Equipment Exhibition in Hainan, Audiowell will showcase its series of ultrasonic flow measurement product solutions developed for the gas and heating sectors, supporting the industry's safe and efficient development with intelligent measurement capabilities.

China International Gas & Heating Technology and Equipment Exhibition

2025.10.22-24

Hainan International Convention and Exhibition Center

Audiowell Booth No.: 4B21

Gas Technology and Equipment Applications

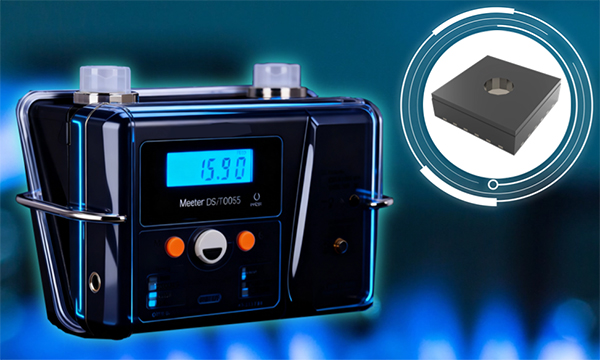

MEMS Ultrasonic Gas Flow Measurement Solution

Integrating the physical principle of sound velocity difference with MEMS technology, the MEMS Ultrasonic Gas Flow Measurement Solution achieves reliable measurement through high-precision Time-of-Flight algorithms and dynamic composition compensation. Its core advantages include low power consumption, long service life, and anti-aging performance. It is particularly suitable for smart meter applications and the Industrial Internet of Things, driving the digital and intelligent evolution of gas flow measurement.

- Enables high-precision detection of low flow rates.

- High integration level, compact size, aligning with the trend of meter miniaturization.

- Mature manufacturing process ensuring good consistency for mass production.

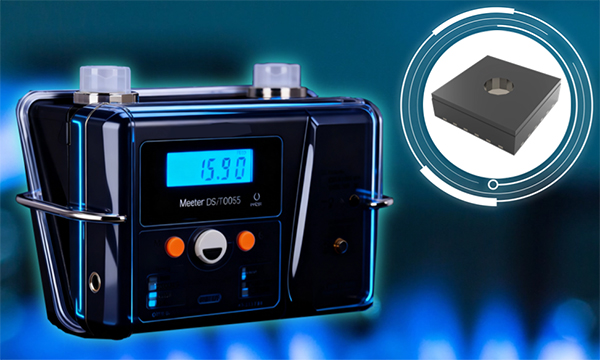

Ultrasonic Gas Flow Transducer

The Ultrasonic Gas Flow Transducer is the core component of an ultrasonic gas meter: it is a type of ultrasonic sensor for gas media. Audiowell utilizes composite materials to create high-performance matching layers, enhancing the transmission capability of ultrasonic signals within gas media. The company has developed high-frequency, high-sensitivity, high-precision sensors with various transmission frequencies like 200KHz and 500KHz, providing accurate sensing data for the iterative upgrade of ultrasonic metering devices for natural gas, coal gas, etc.

- Fabricated with composite materials for high-performance matching layers.

- High frequency, high sensitivity, high precision.

- Various transmission frequencies available (e.g., 200KHz, 500KHz).

Heating Technology and Equipment Applications

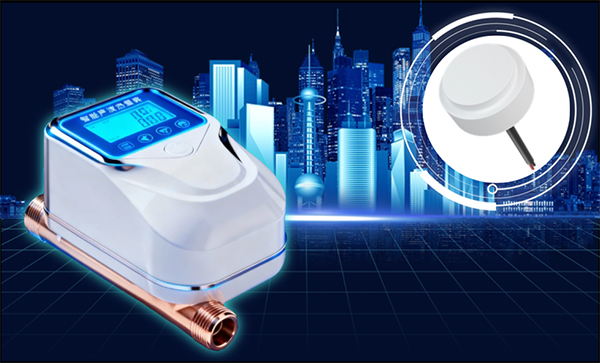

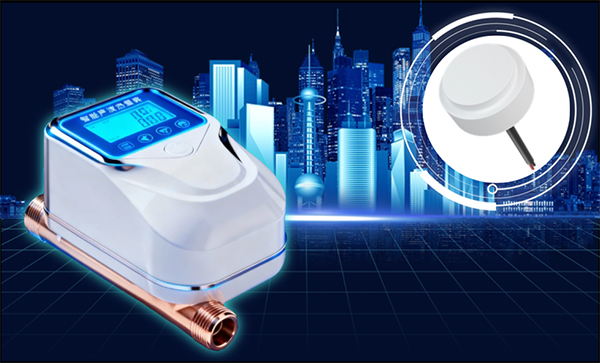

High-Temperature Flow Transducer

Audiowell's High-Temperature Flow Transducer is an ultrasonic transducer for liquid media. It is manufactured using high-pressure resistant metals and other special materials, featuring a highly sealed design that allows direct contact with liquids. This design avoids issues related to unstable pressure and heat resistance, resulting in more stable product performance, reduced interference from environmental factors on signal transmission and reception, and effectively improved response sensitivity.

- Withstands temperatures up to 240°C.

- Capable of long-term operation under pressure of 2.5 MPa.

- Low drive voltage (as low as 5 Vp-p) with good consistency.

- Probe diameter of 16.8mm for wide applicability.

To know more about Audiowell's series of ultrasonic flow measurement product solutions specifically for the gas and heating sectors, we welcome you to visit our booth at the exhibition.

Focus on us

Focus on us