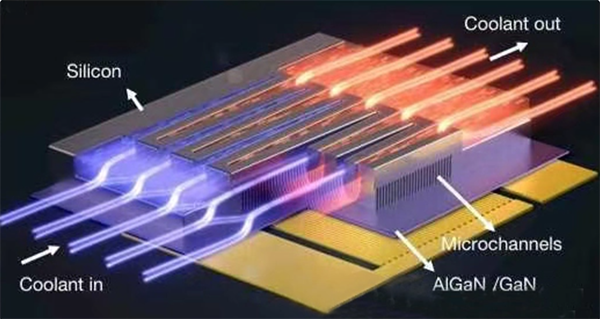

As single-chip power consumption surpasses the kilowatt level and heat flux density climbs to 1000W/cm², traditional air cooling has become inadequate. Only by building a closed-loop system of "on-chip micro-channels for heat extraction + intelligent flow control for heat transport + MEMS based air cooling for heat exhaust" can an efficient, stable, and green thermal management solution be achieved, unlocking ultimate computational power.

NVIDIA's DGX GB200, showcased at GTC 2024, exemplifies this trend, moving to a rack-scale liquid-cooled design for its high-power systems, departing from traditional air-cooled DGX systems.

A New Thermal Management Challenge: From Chip to System

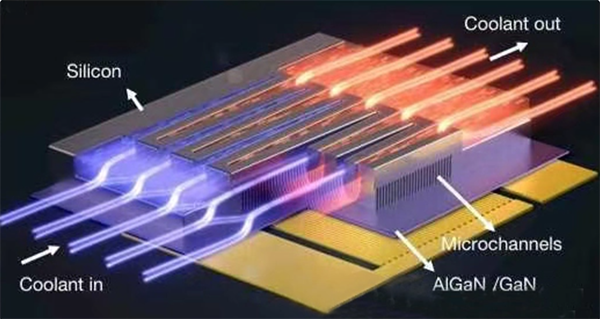

Current chip-level liquid cooling technologies are pushing the thermal front line to the microscopic scale, confronting extreme heat flux. While micro-channel structures can rapidly draw heat away from the chip core, they still face a fundamental issue: if the coolant fails to undergo efficient phase change or maintain continuous circulation, heat will still accumulate within the system, never truly being expelled.

Therefore, relying solely on micro-channels for "heat extraction" is insufficient. Without proper coolant selection and precise flow control, the liquid cooling system can still reach "thermal saturation," leading to performance throttling or even hardware failure. True system-level thermal management must simultaneously address the synergy between "heat extraction, heat transport, and heat exhaust."

The "Heat Transport" Hub: Intelligent Flow Control and Balanced Monitoring

In liquid cooling systems, the high-speed flow and balanced distribution of the coolant directly determine heat dissipation efficiency. We propose the first category of solutions: using high-precision flow sensors to monitor the fluid state within the pipes in real-time, enabling dynamic regulation and early anomaly detection. This technology ensures coolant evenly flows through every micro-channel, preventing localized hot spots, while also enhancing system energy efficiency and reliability – in practical applications, such intelligent flow control can reduce pump system energy consumption by over 40%.

Furthermore, flow sensing capability provides the system with an "intelligent tactile sense," allowing it to handle multiple challenges like sudden load changes, bubble accumulation, and micro-leaks. This elevates the liquid cooling system from "passive heat removal" to "active thermal management."

The "Heat Exhaust" Endgame: Synergy between Phase-Change Cooling and MEMS Air Cooling

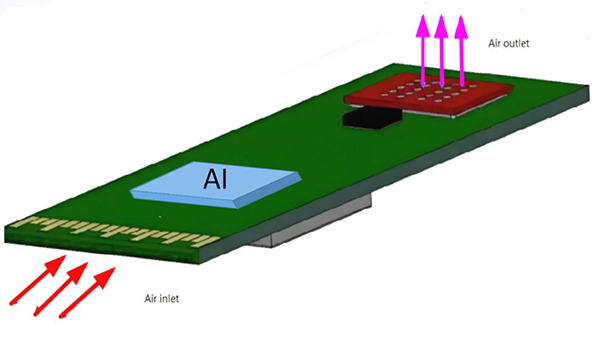

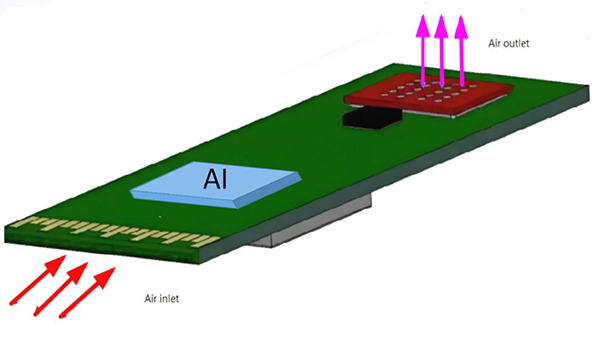

If the coolant does not undergo a phase change within the micro-channels, a remote heat rejection unit is required to ultimately exhaust the heat into the environment. We propose the second category of solutions: combining phase-change cooling with MEMS based air cooling technology for efficient heat rejection at the system level.

MEMS fans, leveraging their millimeter-scale thickness and high-power-density heat dissipation capability, can be integrated onto cold plates, heat fins, or chassis walls to provide targeted airflow over hot spots. In space-constrained edge devices (such as autonomous driving domain controllers, robotic joint modules), MEMS air cooling might be the only feasible active cooling solution.

Phase-change cooling further enhances heat rejection efficiency, allowing heat to be released concentrated at the remote unit, where it is then rapidly expelled into the atmosphere by MEMS fans, creating a true "thermal exhaust."

Closed-Loop Synergy: A New Blueprint for System-Level Cooling

A true thermal closed-loop requires the seamless integration of these three technologies:

Heat Extraction relies on on-chip micro-channels to rapidly conduct heat away from the source.

Heat Transport relies on intelligent flow control to ensure balanced flow and system stability.

Heat Exhaust relies on phase-change cooling and MEMS air cooling to ultimately reject the heat into the environment.

These three elements are indispensable. Only through closed-loop collaboration can optimal cooling performance be achieved across various scenarios – be it cloud data centers, edge servers, or mobile robots – laying the thermal foundation for the Zettascale computing era.

In this systemic battle against thermal limits, the industry is collaborating with chip giants to co-build the next-generation thermal architecture – an intelligent, green, and ubiquitous "Cooling Heart."

Focus on us

Focus on us