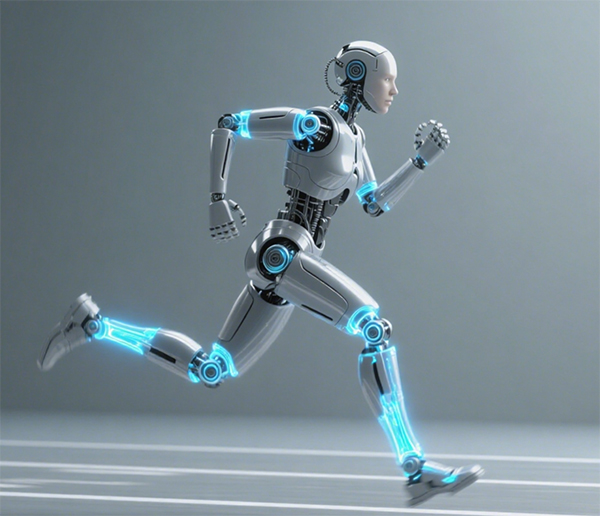

Have you ever seen this scene: an operator sweating profusely while chasing a robot? This isn’t comedy—it’s a real-world dilemma caused by thermal bottlenecks in today’s robotics. At the recently concluded 2025 World Robot Cup, two awkward realities were clearly observed:

1)Operators often have to run after robots, remote in hand.

2)Robots struggle to maintain high-speed operation.

3)The root cause lies in the inability of current robot cooling systems to manage thermal runaway under high-power operation.

Below is a comparison of key performance and energy distribution metrics between a humanoid robot (estimated) and Usain Bolt, the pinnacle of human sprinting:

Item | Humanoid Robot (Estimated) | Usain Bolt (Human) | Key Insight |

100m Time | 21.50 sec | 9.58 sec | Human movement efficiency remains superior |

Total Energy | 8,280,000 J | 11,720,800 J | Humanoid (Tesla): 2.3 kWh; Human (adult): 2800 kcal/day |

Peak Power | 2,240 W (joint instantaneous) | 2,600 W (starting phase) | Human explosive power still leads |

Useful Mechanical Work | 2,350–4,700 J (5-10%) | 16,316–20,395 J (20-25%) | Human efficiency is 2-4× that of robots |

Total Waste Heat | 42,300–44,650 J (>90%) | 61,185–65,264 J (75-80%) | Robot heat proportion higher, but total lower |

Heat Flux Density | >100 W/cm² (local joint) | ~1 W/cm² (average surface) | Robot heat dissipation is orders of magnitude harder |

Core Challenge | Millimeter-scale heat dissipation (triggers throttling) | Muscle oxygen supply & metabolic heat management | Robots hit physical limits; humans face physiological ones |

Energy consumption coefficient ≈1.036 kcal/kg/km (running standard), 1 kcal ≈ 4186 J, air resistance: 8-12% (Source: Journal of Applied Biomechanics 2017), muscle efficiency: 20-25% (Source: Nature 2010), peak power: 2,600W (Source: Journal of Experimental Biology 2010), machine control system loss: 5-8% (Source: IEEE Robotics 2022).

The data shows that performing continuous 100-meter sprints at the same power level, a humanoid robot can complete about 10 runs, while a human can achieve approximately 110 under comparable conditions. This highlights the robot’s lower energy conversion efficiency. Although its instantaneous output nears human levels, the robot’s sustainability is significantly weaker. Humans, with highly optimized muscle energy metabolism and heat dissipation, maintain stable output during high-intensity exercise.

Where Does Bolt’s Energy Go?

Of Bolt’s 65 kJ metabolic energy, about 75% becomes muscle metabolic heat, with only ~10% used to overcome air resistance. Efficient sweat evaporation and respiratory cooling allow him to rapidly dissipate this 50 kJ waste heat, raising his core temperature by just 2–3°C. His true limits are instantaneous muscle power output and aerodynamics.

Where Does the Robot’s Energy Go?

In the humanoid robot’s generated 24 kJ energy, 90% is directly converted into heat, accumulating in tiny spaces like motor windings, gearboxes, and chips. Its performance limit isn’t due to air resistance (insufficient power) but rather inadequate heat dissipation, triggering thermal protection mechanisms.

Thus, the robot’s slowness and the need for humans to chase it aren’t due to “lack of strength” (insufficient energy) but “fear of overheating” (overheat protection). A relatable analogy: placing a 2 kW motor into a 2 cm³ joint cavity is like putting a 1 kW induction cooker into a small pot. The chip temperature can soar from 60°C to 110°C in 30 seconds, instantly triggering thermal throttling and forcing the robot to “slow down to survive.”

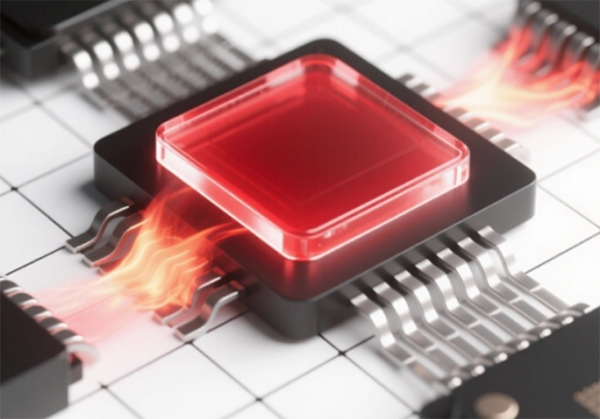

The Thermal Runaway Dilemma: The "Bane" of AI Hardware Miniaturization

Current robot heat dissipation bottlenecks impose severe limitations, especially in extremely confined spaces like dexterous hand joint cavities, where gaps are only 0.7 mm. Traditional 5 mm centrifugal fans cannot be installed. More critically:

Thermal Density Imbalance

Rising chip junction temperatures trigger thermal throttling. The drive chip’s on-resistance (RDS(ON)) has a positive temperature coefficient; for every 10°C increase, resistance rises by ~4%. This creates a deadly feedback loop: temperature rise → increased resistance → exacerbated loss (I²R) → more heat → faster temperature rise. System efficiency plummets, rapidly triggering throttling.

Electromagnetic Interference Inaccuracy

Signal transmission stability declines in high-temperature environments, forcing operators to “feed signals” at close range, severely degrading the experience.

Weak Sustained Operation

Robots frequently enter protection mode, unable to maintain high speeds, drastically limiting application potential.

To solve this “pot too small, fire too strong” (high heat flux density, small cooling area) problem, high-precision, high-efficiency MEMS fans have emerged. Their tiny size allows direct mounting onto critical hotspots (chips and motor drivers), using targeted micro-jets to “blow away” heat, enabling precise cooling and preventing throttling. This avoids overheating-induced performance limits and system failures, unleashing performance closer to motor peaks.

MEMS Fan Advantages:

Extremely Compact

Can be embedded in <1.5 mm spaces, fitting into robot joint cavities, overcoming traditional heatsink size limits.

Precisely Controllable Airflow

Piezoelectric-driven micro-jets enable accurate cooling of motor/chip hotspots, handling heat flux densities >100 W/cm².

Low Power, Low Noise

Breaking the Speed Barrier: MEMS Fans Propel Robots Toward Human-like Speed

For robots to truly match human speed, simply “increasing power” or “reducing weight” is insufficient. Doubling power may improve speed by ~40%, but heat generation squares; reducing weight by 30% may boost efficiency by 15%, but cost and craft constraints apply.

The real gap lies in heat dissipation: humans efficiently expel 75-80% waste heat, while robots convert 90% of energy into heat trapped in millimeter-scale spaces, forcing them to “slow down due to overheating.” The solution isn’t more power or weight reduction but precise cooling—like MEMS fans—unlocking existing hardware’s potential.

We must focus on improving the “quality” of energy use, ensuring each joule converts to motion rather than heat, enabling efficient, sustained high-speed operation without shutdowns or slowdowns.

Cooling as Integral as Chips: The Future is Here

With heterogeneous integration, MEMS cooling units could be embedded directly into chips, achieving the ultimate form of “cooling-as-a-chip.” This redefines thermal management and fundamentally enhances sustainable operation of smart devices.

The “chasing robots” phenomenon in competitions is essentially a desperate call for revolutionary cooling in high-power robotic systems. MEMS fans offer a path toward a more efficient, stable, and sustainable intelligent future.

No more humans chasing machines—let machines run “coolly and efficiently” toward farther horizons.

Focus on us

Focus on us